Stabilization of greenhouses films under severe treatment with pesticides – trends and new products

Mega trends affecting the market: Grow More With Less

- Global population is expected to exceed 9 billion people in 2050.

- Food production needs to increase by 60%

- Water scarcity

- Water use growing double the rate of population increase

- Over 40% of people will be affected by water scarcity in 2050

- Agriculture accounts for 70% of all fresh water consumption (95% in some developing countries!)

- Soil/Land

- Shrinking arable land

- A third of soil is degraded (erosion, nutrient depletion, acidification, salinization, pollution)

Market needs and trends

- Longer lasting films

- Maintaining all functional properties of the film (mechanical, optical, hydrophilicity, etc.)

- Energy saving & improved productivity (thermal screens, double cladding, “cooling” films

- New fumigants. Soil disinfection with chloropicrin. TIF fumigation barrier films should withstand high amount of Cl

- High chemicals stability: Constant growth in Agrochemical usage up to 5,000 ppm Sulfur, 200 ppm Cl,150 ppm Fe. Sulfur – “environmentally friendly” allowed in organic farming and integrated pest management (IPM)

Kafrit R&D Methodology

- Scientific analysis

- Wide data base

- All new formulas are tested in our Lab (accelerated (Xenon Arc, QUV) & outdoor weathering)

- Since 2009 cooperation with Government experimental farm with full agronomic support for new formulations development

- Own Field trials & with leading additive suppliers

- Commercial trials with customers around the globe

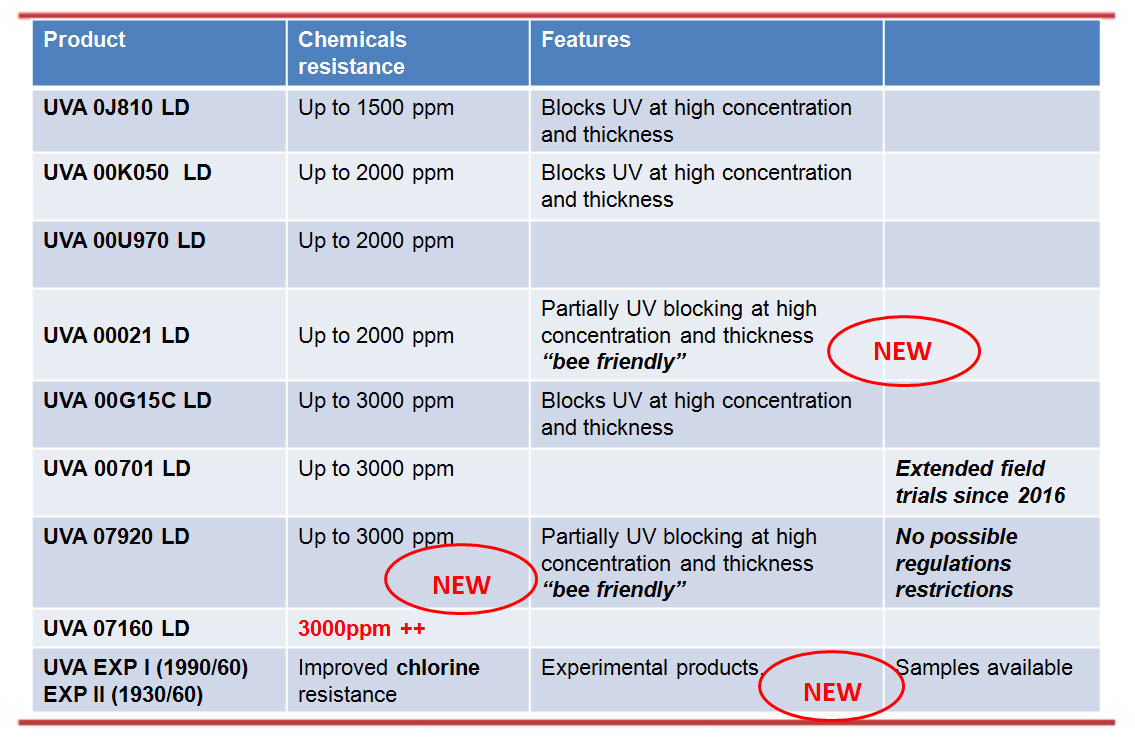

Kafrit NEW products

- Chemical’s resistant: S and Cl

- UVA 00701 LD UVA 07160 LD

- EXP (1990/60) & EXP (1930/60)

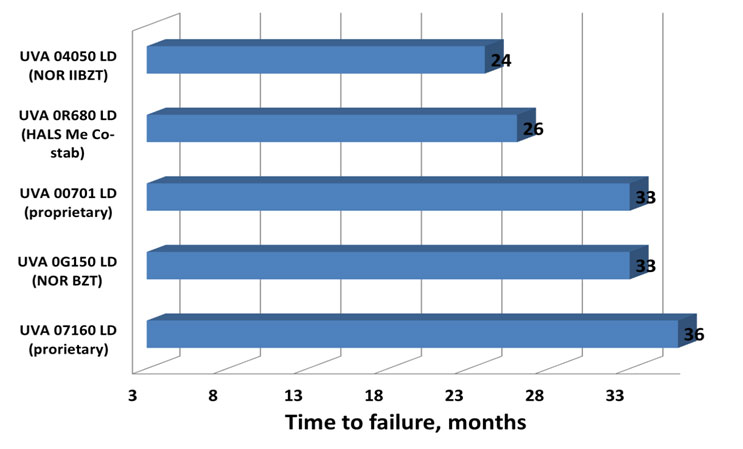

Performance of different UVA MBs under sulfur treatment – extensive field trials

- Walk-in tunnels.

- Experimental farm

- 160 kLy/year

- PE/EVA 3 layers films, 180 mm

- Weekly Sulfur evaporation

Excellent sulfur resistant of UVA 00701 LD, as standard NOR based solution (UVA 0G150 LD).

Superior Sulfur resistance of UVA 07160 LD.

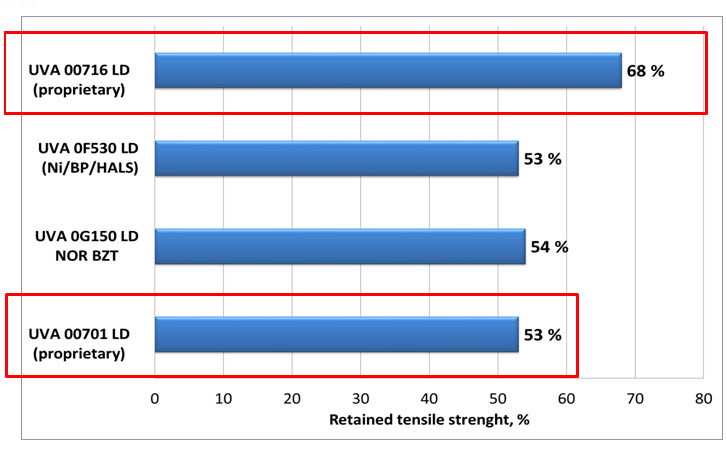

3 years field trials with roses and peppers growers – 180 mm, LD/EVA

- Excellent sulfur resistant of UVA 00701 LD, as standard NOR based solution (UVA 0G150 LD)

- Superior performance of UVA 07160 LD compares to standard NOR and Ni based solutions. 70% retained strength after 36 months at the field. 2700 ppm S

Persistent UV absorption with UVA 00701 LD and UVA 07160 LD

140-160 kLy/year, 2700 ppm S.

UVA 00701 LD keeps on ca. 70% UV blocking even after 3 years at the field.

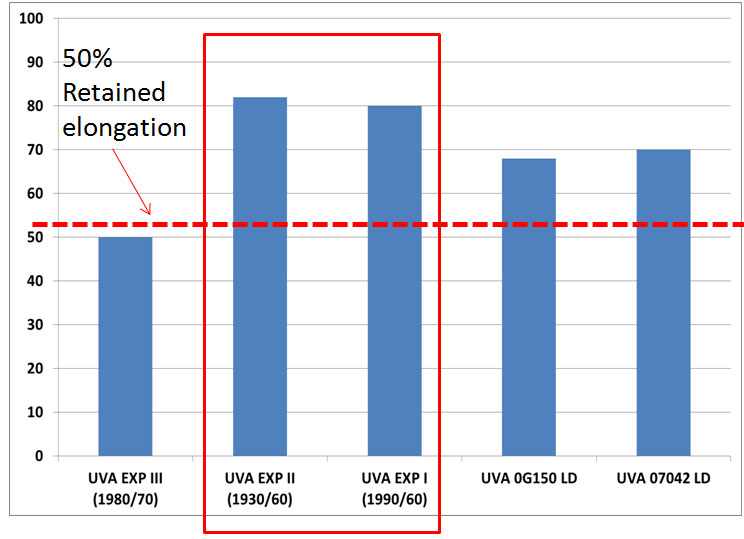

Outdoor weathering with chemical treatment – Chlorine based insecticide

- UVA EXP I (1990/60) and EXP II (1930/60) significantly outperforms standard solutions in Chlorine environment. (more than 500 ppm of Cl)

- Samples are available for trials with customers.

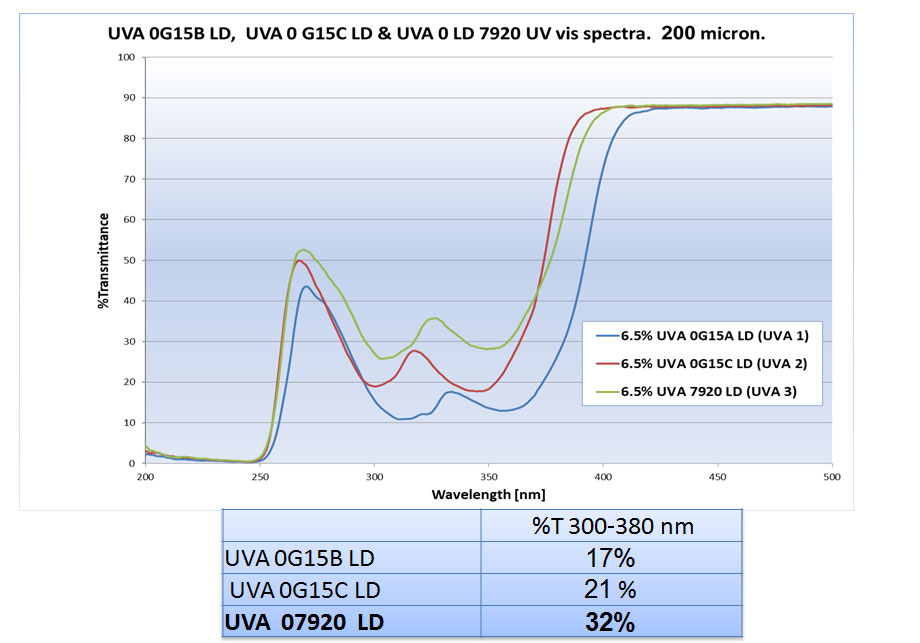

UVA MBs with no influence on pollination & color development – UVA 07920 LD

UV stabilizers’ MB with Partial UV absorption and “UV open”

- Plants that need UV light for color development (eggplants, red salad, nectarines, flowering pot plants)

- Greenhouses where pollination by bumblebees or honeybees is used

- Integrated Pest Management

UV vis transmittance spectrum, 200 micron 6.5% UV MB. Transmittance between 300nm to 380nm

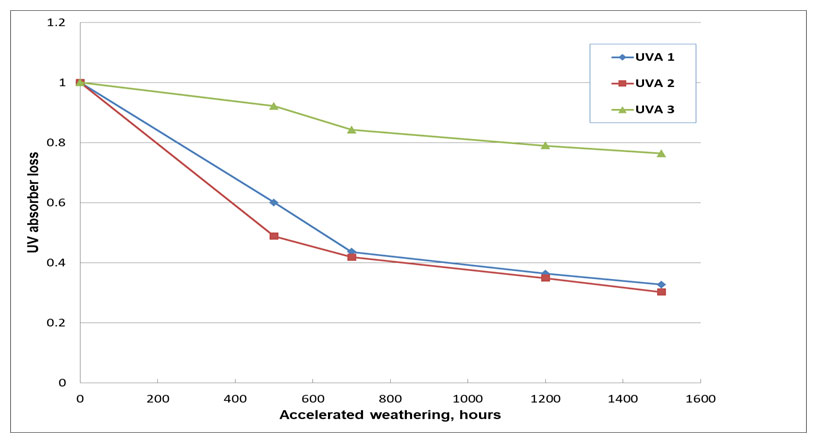

QUVA exposure: UV absorber loss rate, after 1500 hours

- UVA 07920 LD (UVA 3) permit high transmission in UVA region (more than 30% in 200 micron at 6% dosing )

- UVA 07920 LD (UVA 3) has excellent photo-stability (less 15% after ca.1500 hours at QUV)

- UVA 3 is not listed as potential candidate in SVHC list (as vPvB), therefore safety to use. No regulatory restrictions.

Chemicals resistant UV MBs by Kafrit

For more information, please contact:

Hanna Schwartz

R&D Manager

Kafrit Industries (1993) LTD

Tel: +972-8-6809-597 Mobile: +972-50-7891-726

hanna@kafrit.co.il